The S-Type Essential is a fully integrated 19’’ rack mounted cryogenic platform for the continuous, cryogen-free cooling of quantum devices. In its standard configuration, the system provides continuous cooling at 300 mK and “one-shot” operation down to 100 mK – independent of the supply with cryogens.

down to 100 mK

Ø > 140 mm

300 mK

Key benefits

Built for maximum design flexibility, even below 1 K

Versatile cryogenic platform

Despite its compact size the S-Type Essential features a large sample platform to accommodate complex user setups or multiple electronic devices. The System can be easily adapted to integrate, e.g., special wiring, fiber-optics, or custom setups.

Continuous and cryogen-free sub-Kelvin cooling

In its standard configuration, the S-Type Essential features a combination of two ADR units that provide continuous, cryogen-free cooling at temperatures as low as 300 mK. Additionally, both units can be operated in “one-shot” mode to reach temperatures as low as 100 mK for a limited hold time. Both in continuous and “one-shot” mode, the cooling process is automatic and can be controlled through our intuitive graphical user interface. As operation is largely automated, the system does not require special expertise..

Fully integrated cooling solution

The most prominent feature of the S-Type Essential is its full integration in a 19’’ rack, with the cryostat mounted in the lower compartment, and the control electronics in the upper part of the rack. Additionally, the upper part offers enough space to accommodate typical user electronics, so that the complete system will not take up more space in your lab than absolutely necessary. The combination of closed-cycle and magnetic cooling ensures particularly quiet and largely automated system operation, requiring only minimal maintenance.

Typical applications

Innovative cooling for state-of-the-art science and technology

Superconducting Nanowire Single-Photon Detectors (SNSPD)

Cryogenic nanowire detectors are among the most efficient photon detectors available today. They are useful for various applications in metrology, imaging, and communication, including also future fiber-based quantum key distribution networks. SNSPD must be operated well below their superconducting critical temperature of typically several Kelvin. They will benefit from even lower temperatures particularly at the telecom and longer wavelengths. Detector cooling and related applications will benefit from unsupervised long-term cryostat operation, as the S-Type Essential provides continuous cryogen-free sub-Kelvin cooling through a robust magnetic refrigeration process. Despite its small footprint the S-Type Essential offers a large sample stage. It can easily accommodate and operate multiple fiber-coupled detectors and related low-temperature wiring and electronics. Its compact size allows to mount the cryostat in a 19” rack, making it an ideal choice for integrated sensing and communication applications.

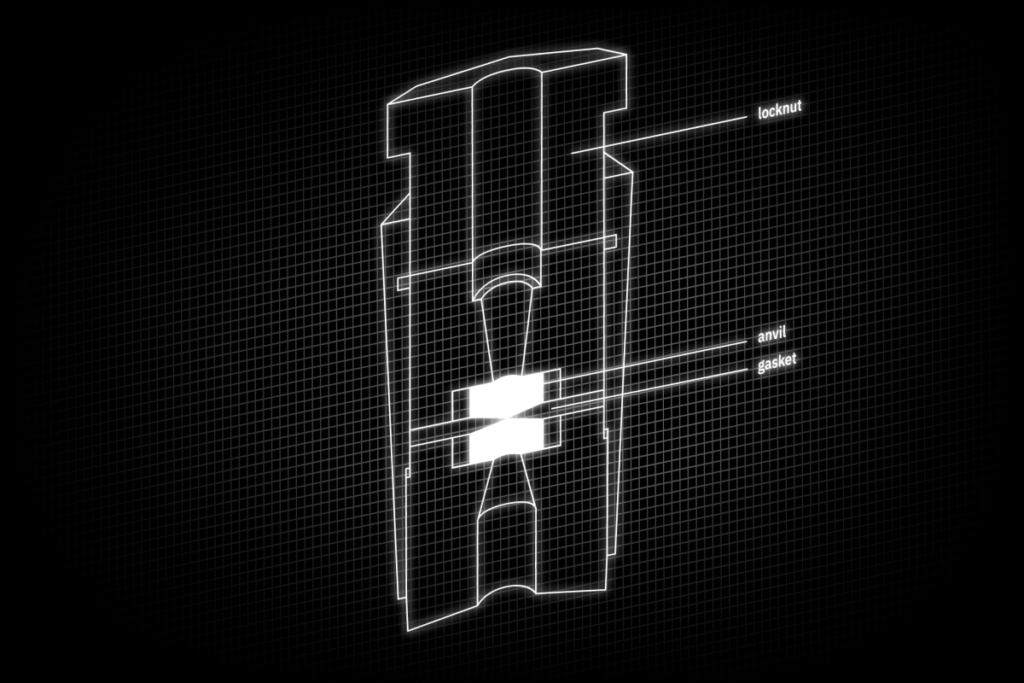

High-Pressure Measurements

Materials with strong electronic correlations are often susceptible to the application of pressure. Using high-pressure techniques like piston-cylinder or Bridgman cells, physical properties such as the magnetization, susceptibility, and resistivity can be studied as a function of temperature, magnetic field, and pressure. This allows to map out complex phase diagrams, to tune materials towards low-temperature electronic instabilities, and to investigate their behavior in the proximity of a phase transition. The L-Type Rapid is a fast-cooling cryostat and therefore ideally suited to study pressure cells, where the pressure must be changed frequently and ex-situ. The sample puck used in its sample loader offers enough space to mount different high-pressure clamp cells. More complex experimental setups that require, e.g., gas-activated cells for in-situ changes of the pressure or in-situ pressure determination using ruby fluorescence can be implemented using the S-Type Essential. It offers a large sample platform and can be easily adapted by the user to meet their individual requirements.

Our customers

We are trusted by leading companies and research institutions around the world

Performance data

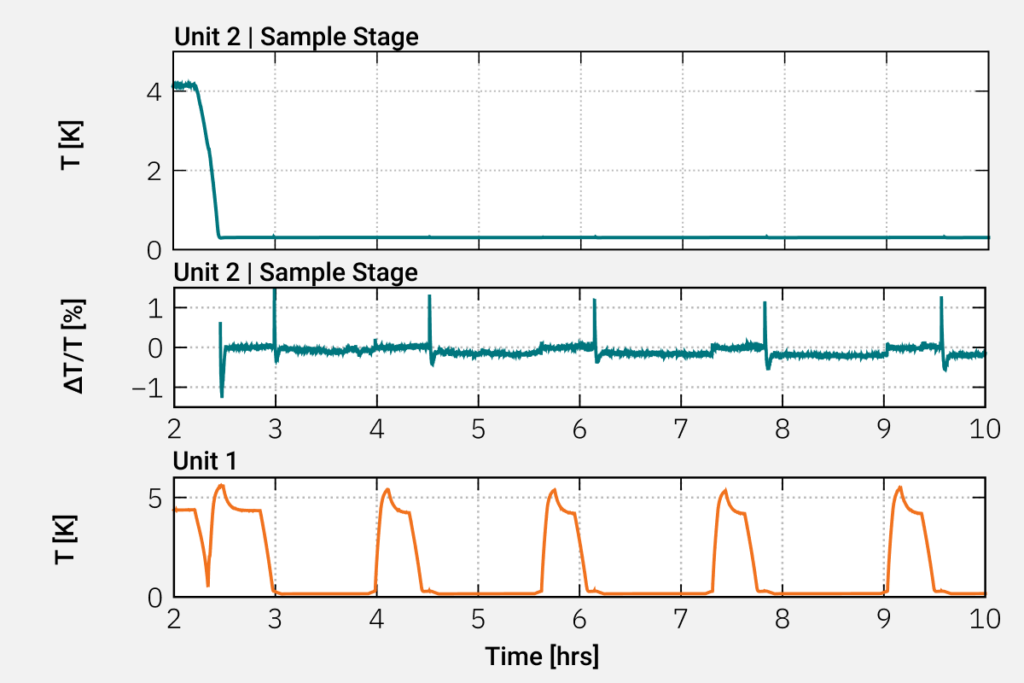

Continuous solid-state cryogenic cooling

Continuous operation at 300 mK

Conventional adiabatic demagnetization refrigerators (ADR) allow only for “one-shot” cooling. By combining multiple ADR units, kiutra’s cryostats can provide both “one-shot” and additionally continuous sub-Kelvin cooling (cADR) independent of the supply with cryogens. In its standard configuration, the S-Type Essential uses two ADR units to generate continuous magnetic cooling. The figure shows the temperatures of both ADR units running in cADR mode at 300 mK. While the first unit cycles between the 4 K main heat bath (provided by the cryocooler) and a temperature below the target temperature, the second unit controls the sample temperature. As a result, the sample stage can maintain a constant temperature of 300 mK with a typical temperature stability <0.1 %, and a slightly reduced stability <2 % when activating its heat switch to initialize the regeneration.

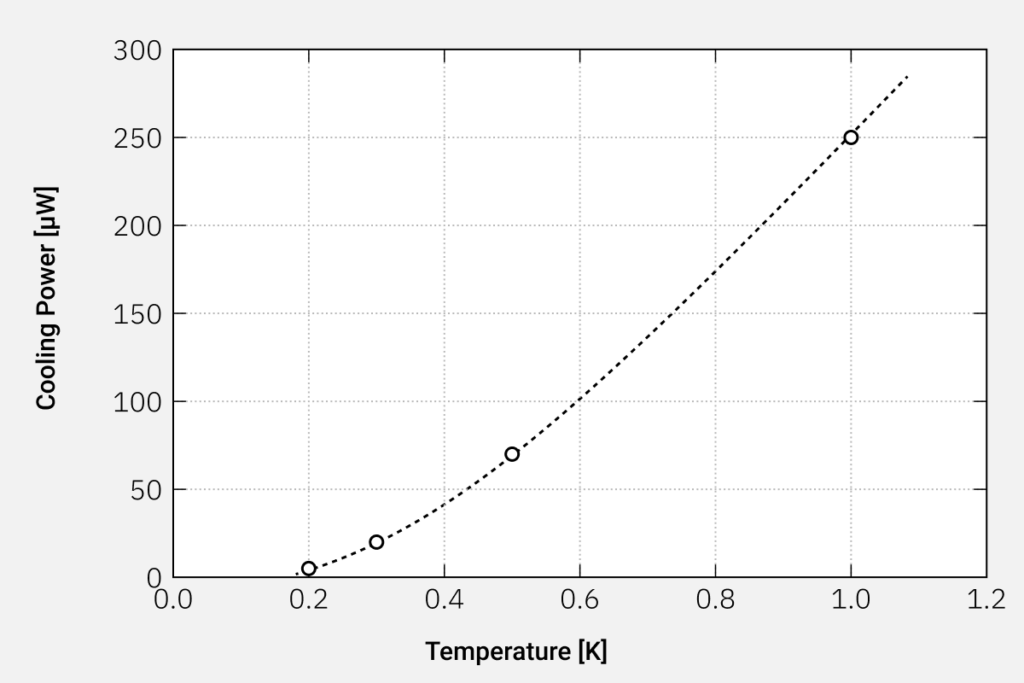

Cooling power

A detailed knowledge of the cooling performance of a system is essential for the realization of cryogenic applications. This graph shows the cooling power of the S-Type Essential, measured at the sample platform with the standard 24 lines DC wiring, sample heater, and thermometer installed.

Scope of supply

Cryostat

Sumitomo RP-082B2 closed-cyle pulsetube cryocooler, 1W 4.2K, 40 W @ 45 K

Sumitomo F70H water-cooled indoor helium compressor, 20 m flexlines

Two ADR units for one-shot continuous operation:

- 2 ADR magnets

- 2 Heat switches

- 2 Cooling media

Wide range pressure gauge

Integrated passive quench protection

Instrument Control

kiutra Modular Control Unit (MCU):

- Base Module

- Power Module

- Drive Module

- 2x Load Module

kiutra Compressor Control Unit (CCU)

Temperature monitor & controller

Calibrated temperature sensor on sample stage

Temperature sensors on cryocooler cold stages and first ADR unit

Sample heater and warm-up heater

User PC with pre-configuration Python-based instrument control software and high-definition display

2 x Digital high frequency magnet power supply

User breakout

Filtered temperature sensor breakout

Specs

This system is currently being developed and tested. It will become available approximately in Q4/24. The specifications listed here are preliminary specifications expected to be reached and will be updated once the system is out of the development phase.

| System size (cm) (w x l x h) | cryostat & electronics compressor | 80 x 210 x 80 54 x 45 x 50 |

| System weight (kg) | cryostat & electronics | < 750 |

| Size of sample platform (mm) | diameter height | >140 >50 |

| System cooldown time (hrs) | 32 | |

| Continuous operation (K) | 0.3 | |

| Cooling power (µW) | @ 500 mK @ 1K | >50 >160 |

| Operation time (hrs) | @100 mK | 3 hours |

| Temperature stability | typical while switching stages | < 0.1 % < 2 % |

Available options

Up to 4 optical fibers

to run detectors or photon sources

Up to 16 RF lines

and up to 48 DC lines